What are the duties and responsibilities of a Production Planner? They make sure there's enough material and equipment available, maintaining clean working spaces so they can run smoothly without interruption or risk of damage. Production Planners to account for every detail in the production process. High school diploma Further education or certification is preferredįrequently asked questions What does a Production Planner do?.Strong organizational and problem-solving skills.Working knowledge of MS Office and ERP systems.Experience in MRP II (Manufacturing resource planning).Excellent knowledge of production planning and quality control principles.Proven experience as production planner.Collaborate with quality control, warehouse and other staff.Prepare and submit status and performance reports.Obtain output information (number of finished products, percentage of defectives etc.).Address issues when they arise aiming for minimum disruption.Monitor jobs to ensure they will finish on time and within budget.Schedule shift according to production needs.Assign workers and other staff to particular production operations.Determine manpower, equipment and raw materials needed to cover production demand.Plan and prioritize operations to ensure maximum performance and minimum delay.Coordinate production workflow for one or multiple products.The goal is to ensure the smooth and cost-efficient flow of our production operations. Advanced communication and computer skills are very useful for the role. They are organized and results-driven with great problem-solving skills. You will be the one to ensure our goods are produced on time for distribution in a profitable manner.Īn excellent production planner is well-versed in production procedures and ways to optimize them. We are looking for a qualified Production Planner to organize production according to demand and quality standards. Determining manpower, equipment and raw materials needed to cover production demand.Planning and prioritizing operations to ensure maximum performance and minimum delay.Coordinating production workflow for one or multiple products.That insight, along with consensus on the most immediate improvement priorities means your organization can take a pragmatic approach to build on existing planning and scheduling strengths.Production Planner responsibilities include: The best approach for every company is to understand the processes already in place, the tools and systems supporting them, and the needs and concerns of the people involved. Understanding the Value of Planning and Scheduling Throughout the EnterpriseĮven within a single industry sector, all companies have vastly different customer requirements, strategic objectives, and operating environments. Standalone solutions that also integrate real-time plant scheduling with ERP, OEE/MES, data collection, and supply chain systems.

Apply advanced scheduling algorithms to balance demand and capacity.Address tactical planning and scheduling concerns within a several-week horizon.Enhance strategic plans with long-term advance planning.Improve demand planning with fast, easy-to-create make/buy plans.Standardize and coordinate planning and scheduling globally.Quickly respond to real-time production disruptions.Automate production schedule templates to fit production constraints.

#PRODUCTION PLANNING SOFTWARE#

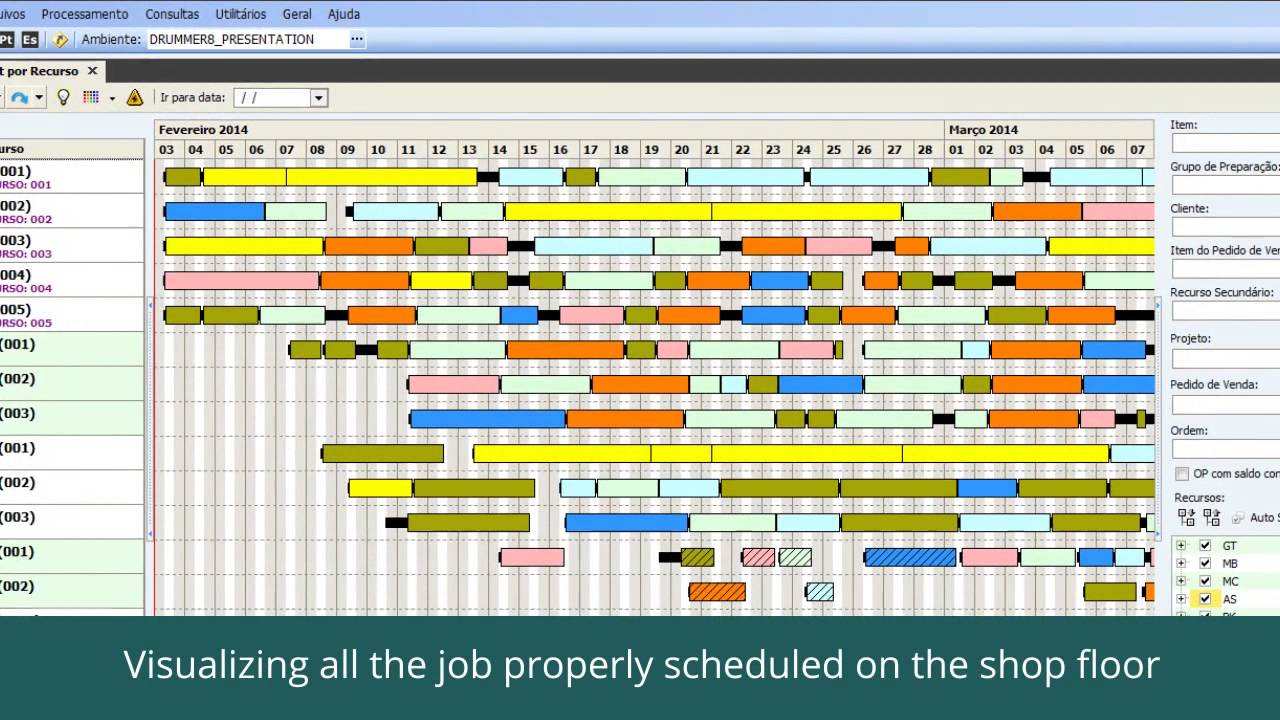

Manufacturers that use production planning and scheduling software to conduct effective scheduling planning, so they maximize throughput with real-time visibility and collaboration.

Your production schedule has a direct impact on on-time delivery, inventories, and profitability.

0 kommentar(er)

0 kommentar(er)